I held two roles at Plenty. I first joined as a design engineer mainly responsible for the “post harvest” and then moved into a management role.

Post Harvest

As an engineer, I was directly responsible for some of the largest capital projects (both by dollar value and space allocation) on the farm which involved taking the product from harvest to final packaging. The total installed cost of the entire Post Harvest line was around $12M USD.

Project Requirements

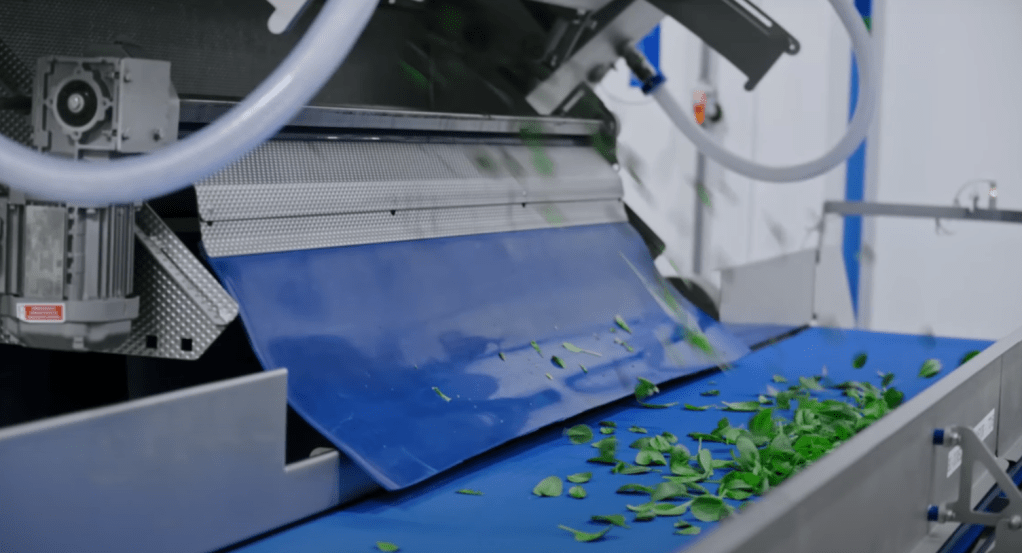

The overall vision for this project was that the first person to ever touch the leafy greens was the consumer in their home (which implied automation). The peak packaging rates and surging nature of the operation also led to the decision to fully automate this process.

Another key constraint to the project was the tender nature of the product. Indoor leafy greens are much more tender than the field grown alternative and tend to

The high level process for packaging the leafy greens is:

- Weighing

- Inspection

- Temporary storage

- Blending

- Clamshell packaging

- Case packagain

- Palletization

Concept

At the onset of this project it was critical to get a concept nailed down. We were “shoehorning” our entire farm (seeding, grow rooms, nutrient skids, warehousing) into a pre-existing structure and every other team wanted as much space for their equipment! A spirited landgrab ensued and I led many discussions with product, operations, quality and engineering to determine the exact needs of the space.

To ensure territorial negotiations could be be most effective, I generated a representation of each block needed for the process including conveyance (a large contributor to space claims).

Some of the equipment (optical sorters and packaging machines) was straightforward based linearly on peak throughput requirements. This could be somewhat easily estimated by multiplying target yield per grow tower (see image) and cycle time per tower to get output in terms of weight and comparing that to the finished packaging targets by crop (4.5 oz or 10oz packages were the two sizes on the menu).

Some of the final recipes called for mixes of different products (spring mix or other mixes) and some with first and second growth towers (some crops could be harvest and regrown on the same roots. Second growths had slightly different texture and flavor).

I generated some number crunching spreadsheets that allowed me and the product team to scenario model for worst cases, new products, etc and easily modify equipment needs and sizing.

Getting peak rates allowed for the majority of the concept to be generated. One key remaining section was the need for temporary storage. This was largely affected by (the undecided) recipe mix and farm orchestration (which towers come out when).

For example, a recipe may call for:

| Ingredient | Percentage |

| Crop A | 40% |

| Crop B | 35% |

| Crop C | 25% |

The orchestration of the farm on the other hand may be in the order of Crop C, Crop B, Crop F, Crop E (both unrelated) and finally Crop A.

I evaluated several options such as using large hoppers, large conveyors, ASRS systems and tubs to store product temporarily.

The tubs ended up being the most favorable for a number of reasons. They were stackable, cleanable and could be used in flexible quantities to generate mixes easily.

Finding the Right Integrator

Once the teams had alignment it was time to figure out who in the world could help bring these concepts to life.

There were three key areas to subdivide into:

- Product preparation

- Primary packaging

- Secondary packaging

Secondary packaging (which is case packaging clamshells and palletizing cases) was not in a clean room (didn’t need washdown) so could be handled by fairly traditional integrators.

Primary packaging (putting weighed product into clamshells) is handled almost exclusively by multihead weighing technology at these rates. There are a handful of big players such as Yamato, Multipond and Ishida who partner with integrators for the turnkey design.

The Product Preparation area required slightly more customization. The integrators required skill with washdown design, leafy greens specific experience. This significantly narrowed the field of integrators to a few North American and several European integrators.

With concept in hand, the team and I were off to trade shows, vendor visits and other food plants to find the right solutions and companies to work with. After reviewing multiple bids, revising the concept to better fit reality (and changes to farm requirements!!!) the Plenty procurement team was sicked on the poor vendors. In the end, one strong contender remained for each zone and POs were issued.

Execution

Following contract negotiations, design was promptly kicked off. In order the bring my concept to reality I had to explicitly communicate to the vendors layout needs, facility information, product needs and controls.

I pride myself in my ability to build relationships and trust with projects teammates. This was fully on display throughout this project as teams were spread across multiple continents and time zones. I forged strong personal relationships which proved valuable whenever issues came up or changes were needed.

Some of the key work I led here was:

- mechanical teams to design the hardware and lay the space out

- controls team and theirs to design the pseudocode and functional description that made the logic for the machinery

- electrical teams to specify facility drops and routing (especially in washdown areas)

- maintenance and operations teams to design catwalks, cleaning stations, tool change areas and spare parts areas

- safety teams for general machine safety and ergonomics

- redesign of packaging to be destackable

- redesign of labels to work with equipment

Overall, the projects were completed on schedule and on budget. I personally conducted the Factory Acceptance Testing of all hardware to verify rate, functionality and controls before handing off to the operations and construction teams for install.

Other Projects

Follow my work on Post Harvest I was tasked with overseeing the completion of several in-house machine design projects that had previously been kicked off. These included:

- Tower washing

- Tower buffering

- Harvesting

Tower Washing

For tower washing I worked with the R&D team to conduct major design improvements which required extensive testing. As a key part of the line for crop health, sanitization was a top priority.

Some of the key challenges were:

- The tangly nature of roots and stems made removal a challenge. Patented methods for removal were developed to handle this including close cut sawing and pressing with wheels.

- The towers were a new design completely incompatible with the older farm generations. This required coordinating custom growing of test material. This would require weeks of advanced planning.

- Tower breakage due to aggressive root removal. This needed to be optimized through many trials and errors including process changes on the cleaner and revisions to tower manufacturing.

- Microbial level sanitization requires high pressure for removal and chemicals which cause occupational hazards due to the misting of sanitizer into the air. This was solved with fresh water rinsing and additional ventilation.

- Removing roots out of the building. This was handled by screw conveyors but ideally would have been some flume systems.

Tower Buffering

This project involved stacking towers after cleaning. The need for this project was mainly a result of how the farm was orchestrated and how towers were re-inducted into the grow rooms but also helped with the dwell time of cleaning chemicals (increased exposure time allowed bacteria to be killed).

The design was straightforward and included a gantry crane overhead and a series of stainless racking.

I designed the first iteration of the racking and framing before handing off to an integrator for final manufacture.

Harvester

This machine does the cutting of the lettuce off of the towers. Some key requirements were the ability to change blade offset and to sanitize blades between crops.

My role on this project was mainly vendor management and coordination of testing.