At Ripcord I was the lead of the mechanical team. I joined early (Just after Series A) and was tasked with bringing the vision of scanning real world documents to extract valuable data and information.

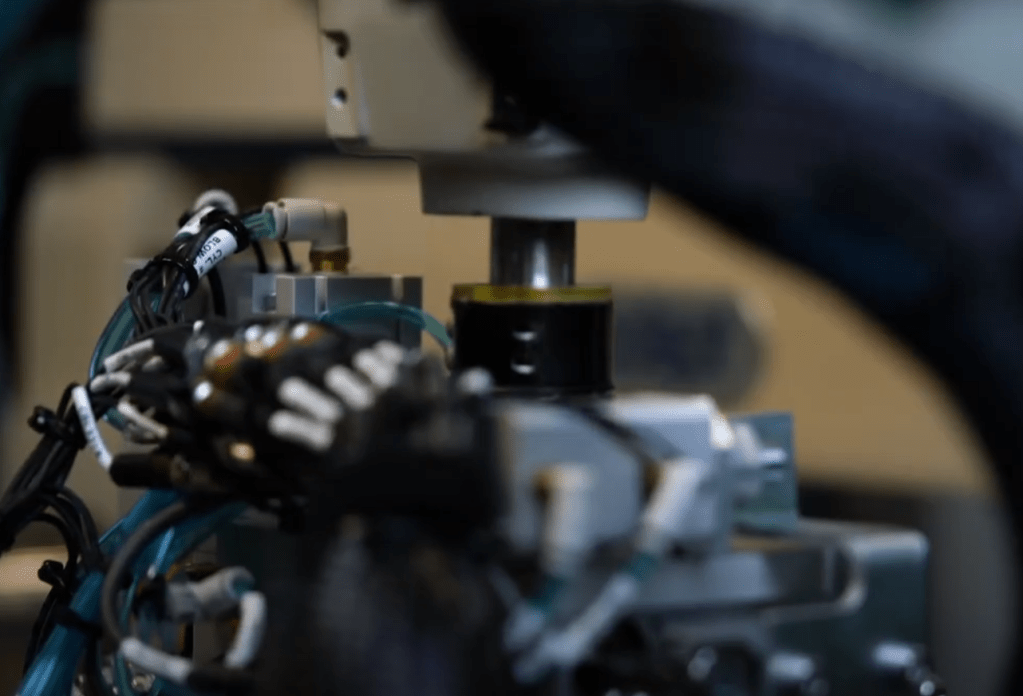

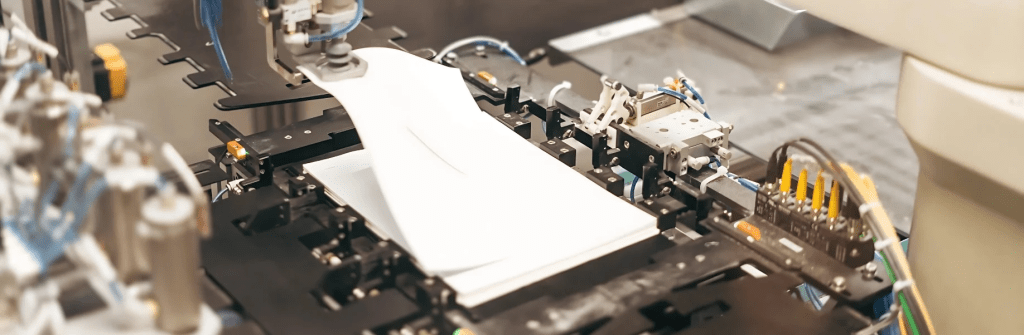

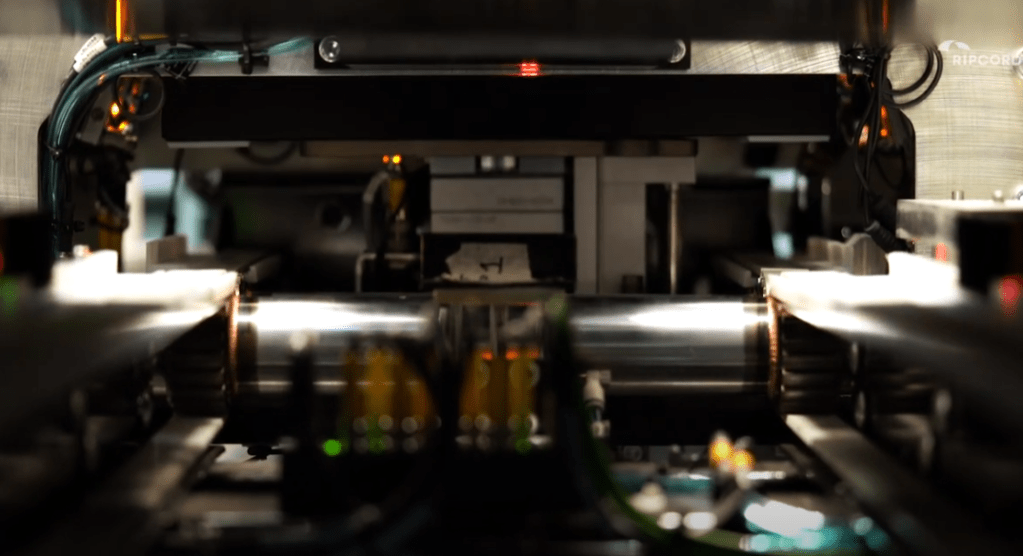

When I joined, the team had worked out a few of the basic concepts but these needed to be turned into a full fledged automation machine. I handled the design of end-of-arm-tools, totes, tote handlers and other pieces of novel equipment. I took these elements from concept through prototyping.

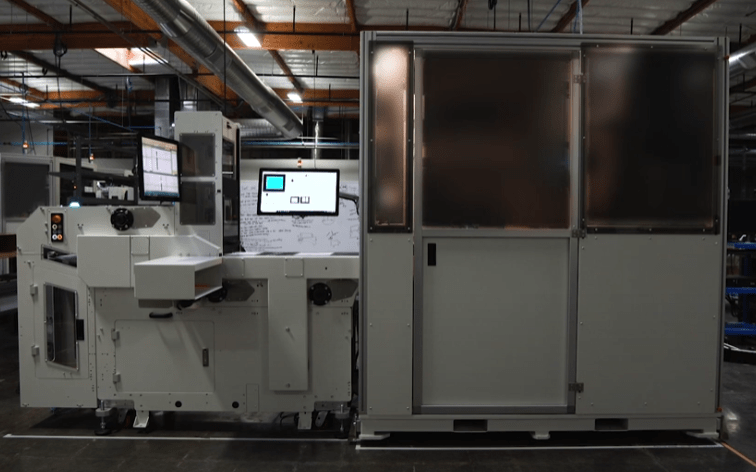

I then worked with integrators to handle the bulk of the remaining cell designs which was then manufactured.

I led the team through 5 major machine revisions, ultimately building out a facility in Hayward, CA and the next version of the cell which was deployed in Japan at a customer facility.

As the team grew, I also oversaw efforts to design the preparation stations and carts, key pieces of the operational efficiency of the company.

Links to the video can be found here: